Restoration of an antique grandfather clock

An antique clock always has two tasks.

An antique clock always has two tasks.

On the one hand, it should look beautiful, it should fill the place where it is placed with its charm and it should contribute to an individual interior design.

On the other hand, it should of course function. It should show the time, perhaps even the date and the phases of the moon. It should strike - and exactly when an hour has passed. Not a minute earlier and not a minute later...

What is done during the basic overhaul of an antique clock?

Antique clocks run for many years and decades, even centuries if they are properly maintained. But one thing must not be forgotten: mechanical watches not only have the proverbial many interlocking cogs.

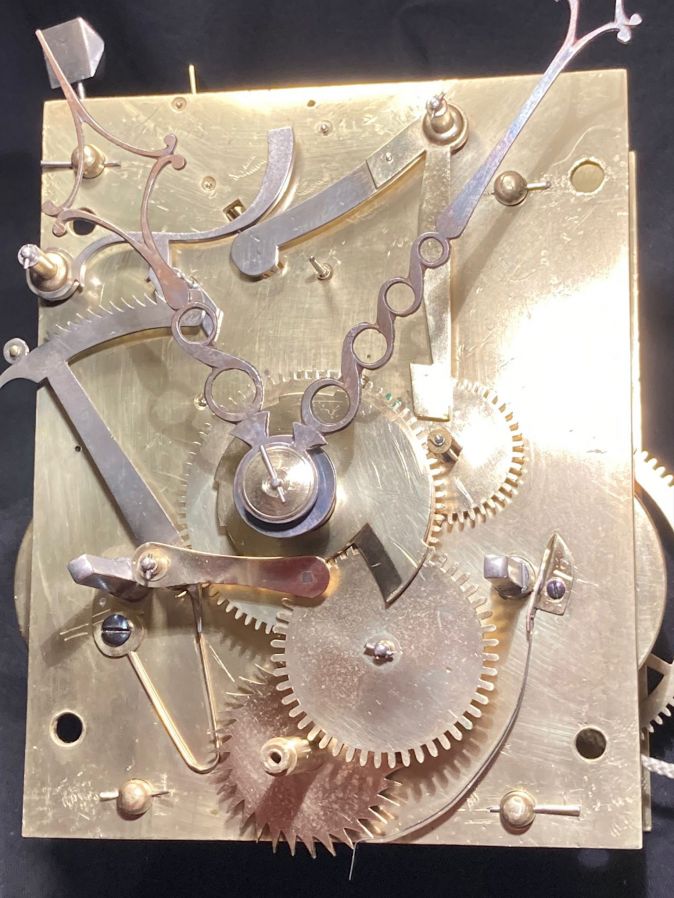

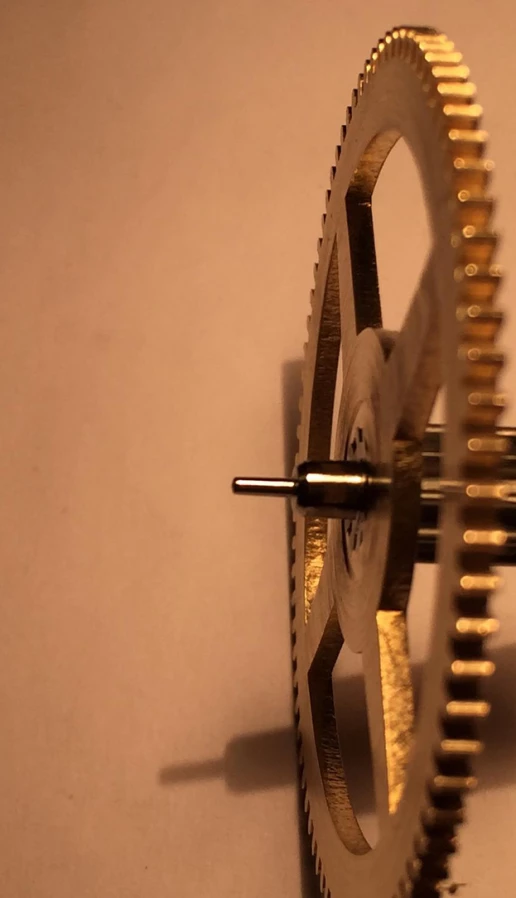

The most frequent wear is caused by permanent friction, especially on pivots, bearings, pallet pallets, levers, drives, etc. For example, an escape wheel pivot turns tens of millions of times in its bearing over the years. This is an enormous achievement, but one that does not leave the components of an antique clock unscathed. Where there is movement, where forces act, where metal works on metal, there is always abrasion.

In order to reduce wear through friction, a film of oil is applied between the journal and the bearing, for example. However, this oil increasingly mixes with dust and abrasion particles and thus loses its lubricating effect. Instead, a viscous mass with an increasingly abrasive effect continuously forms. The bearings run out, the journals wear in.

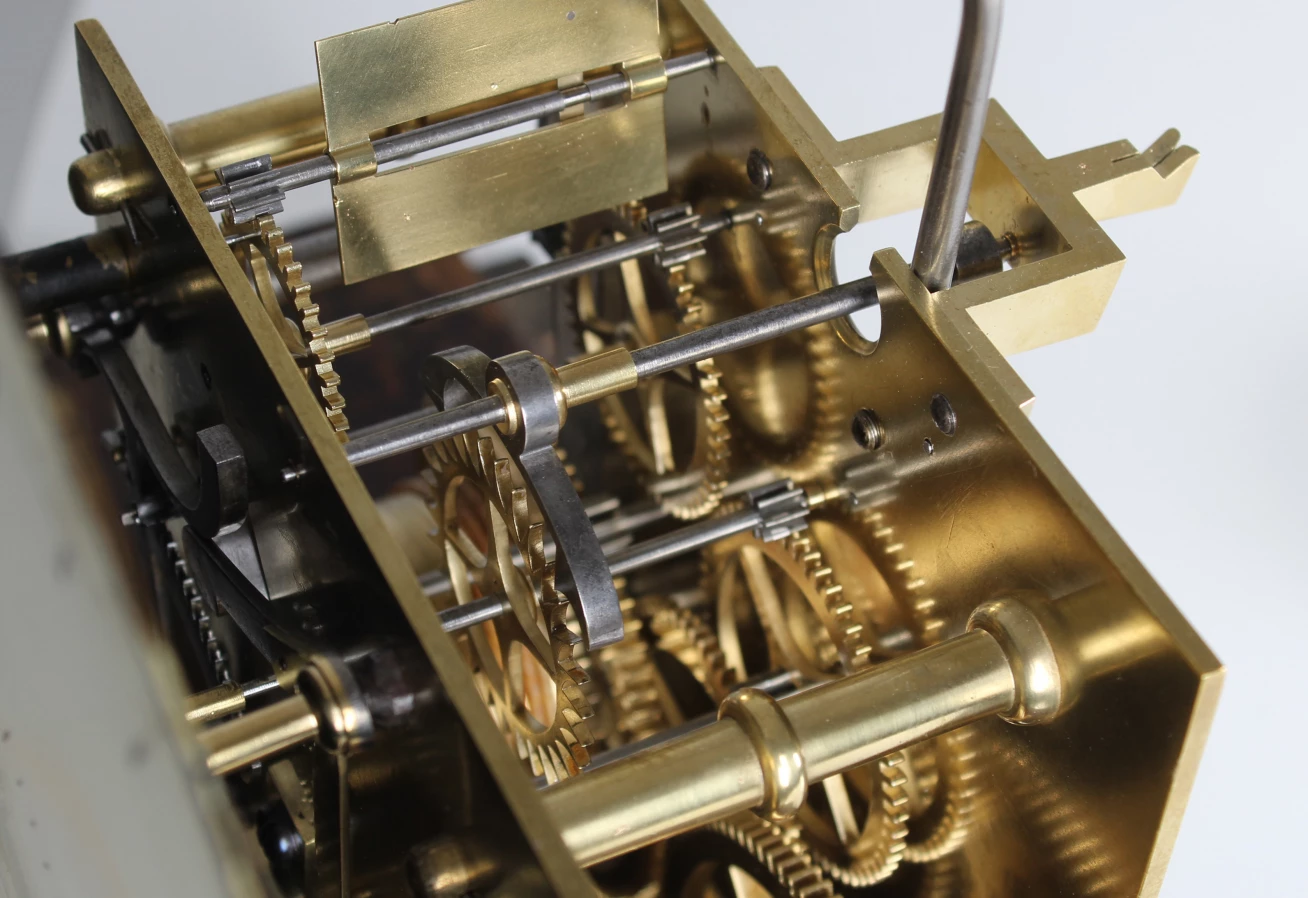

In the course of a general overhaul, the movement is completely disassembled. All parts are checked for functionality and correct fit. Where necessary, bearings are replaced, pivots are rounded off and all contact surfaces on levers, pins and teeth are not only simply cleaned, but smoothed and polished. Because smooth surfaces create less friction and also form a kind of corrosion protection. Of course, all the necessary areas are then treated with appropriate special oils.

Thus, overhauled from the ground up, the movement can now serve for a long time again.

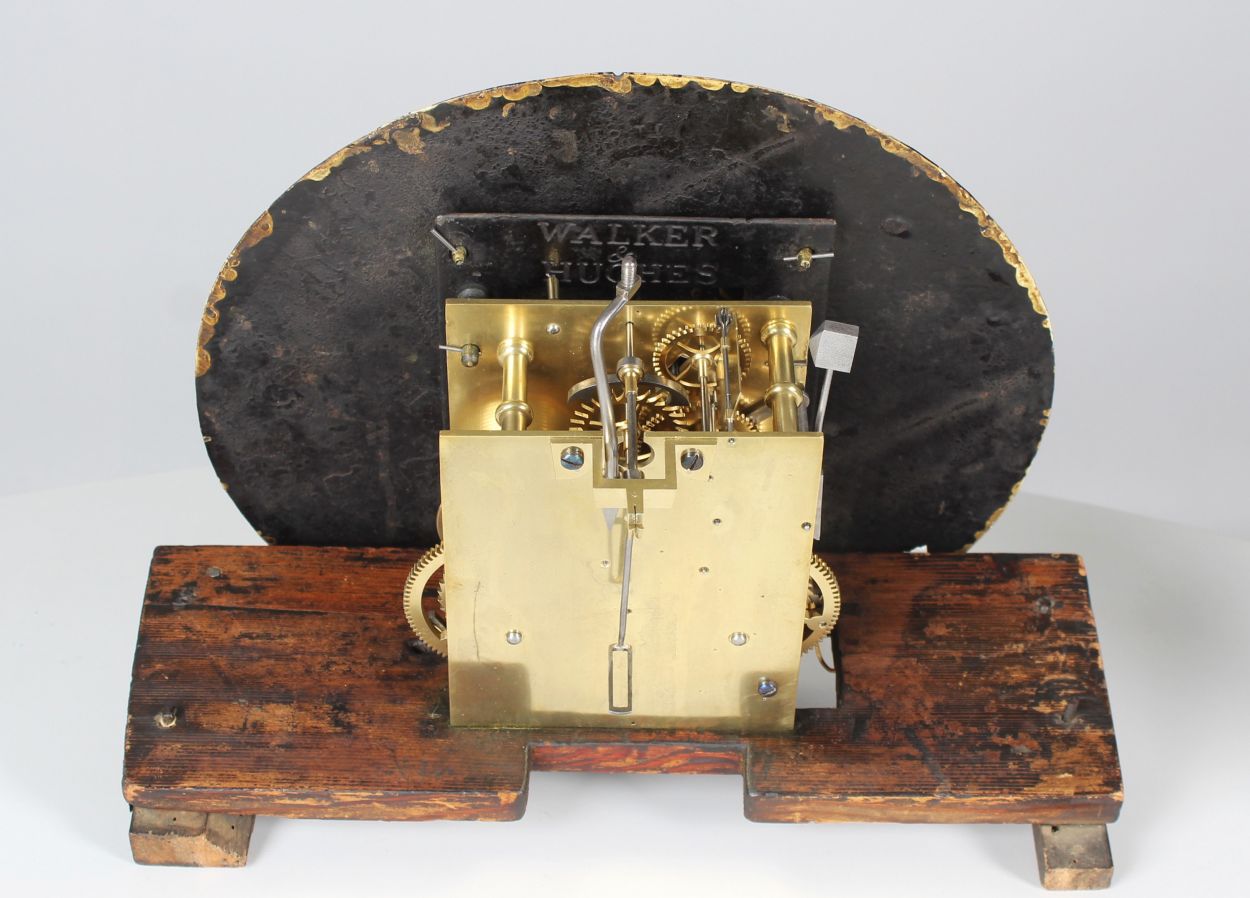

Restoration of an English grandfather clock

Restoration of an English grandfather clock

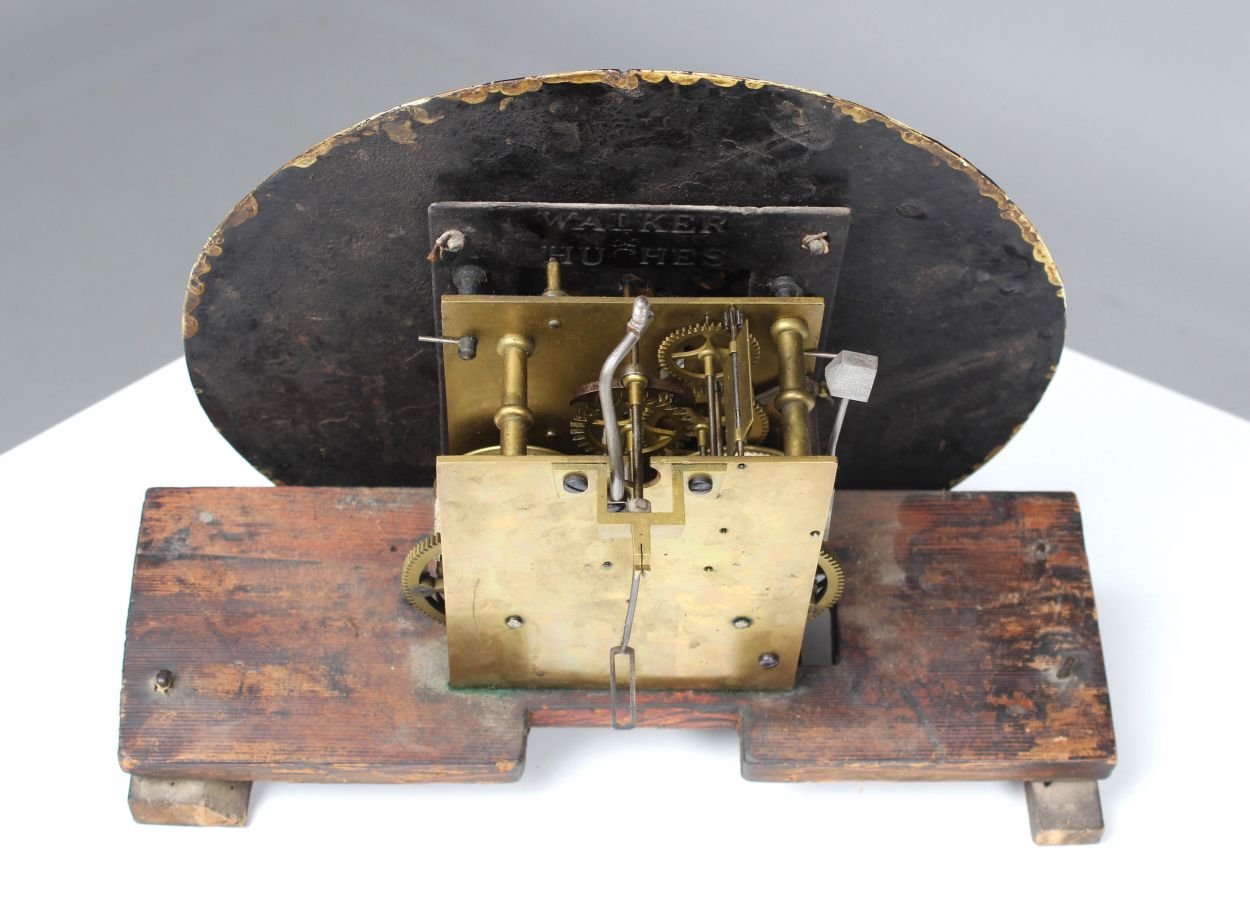

The case of the grandfather clock presented here was cleaned first. The use of abrasives was almost completely avoided, so that the deeper defects and unevenness were deliberately preserved.

The missing metal balls at the top of the head were turned from wood and gilded. The non-original knob for opening the glazed door was removed and the old locking mechanism from inside the body was restored instead.

The shellac polish restored strength and "depth" to the wood.

The movement showed a solid and overall well-preserved basic substance. In addition to the usual measures of a basic overhaul, some items nevertheless required special attention:

-The shapely, handmade hands were freed from crumbly varnish residues, so that the elegant, steel-blue hue could be beautifully shown off again.

-The missing pendulum spring was renewed from blued spring steel. The threaded rod on the lower side of the pendulum was replaced and a knurled nut was added for adjustment.

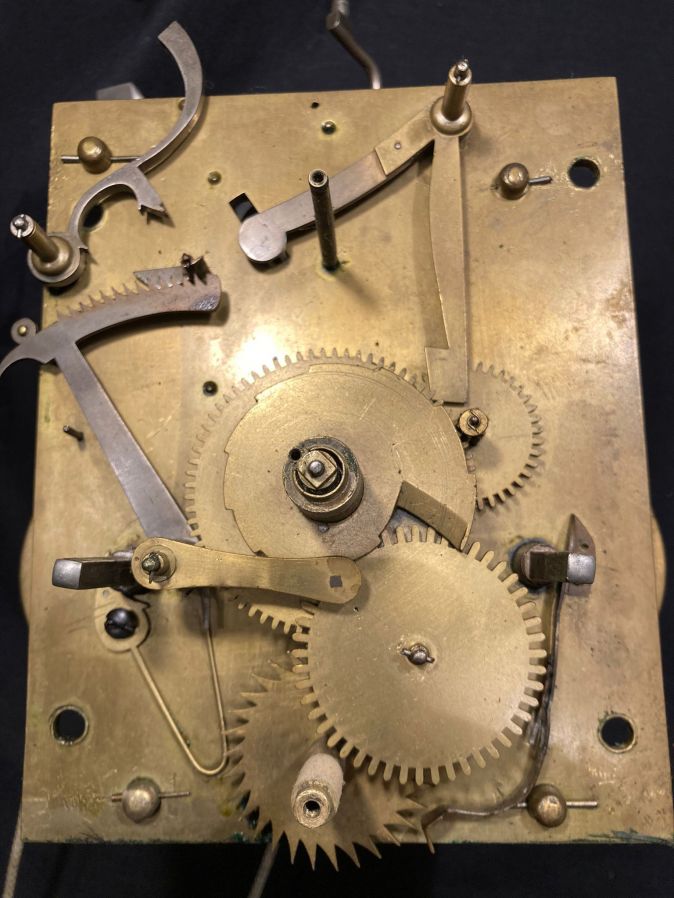

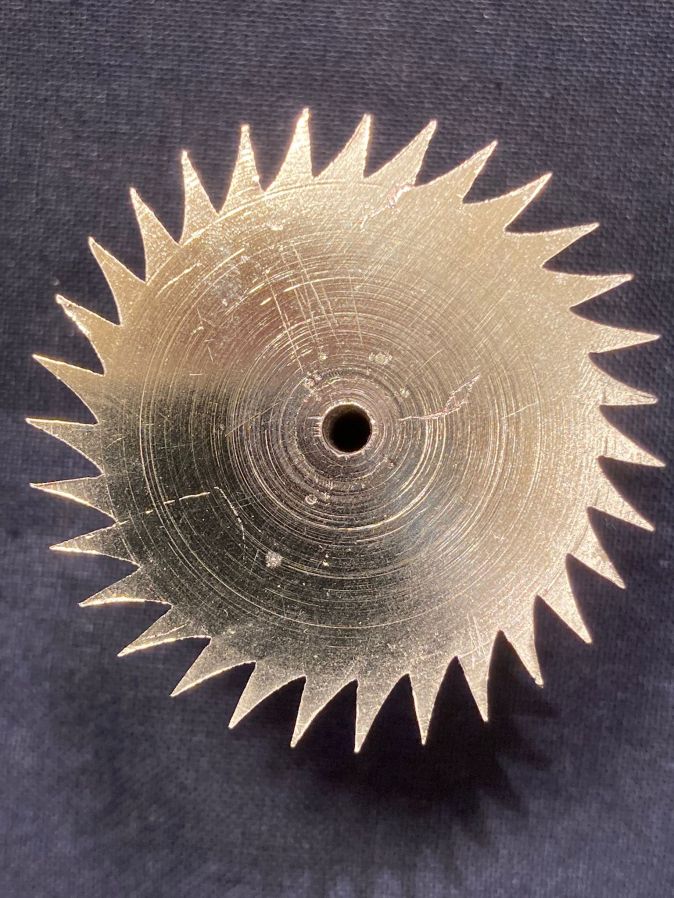

-Bent teeth on the date wheel were straightened and the wheel was re-rounded due to unevenly long teeth (see photos). The corresponding locking spring was broken and out of order. It was newly made of spring steel and blued (see photos).

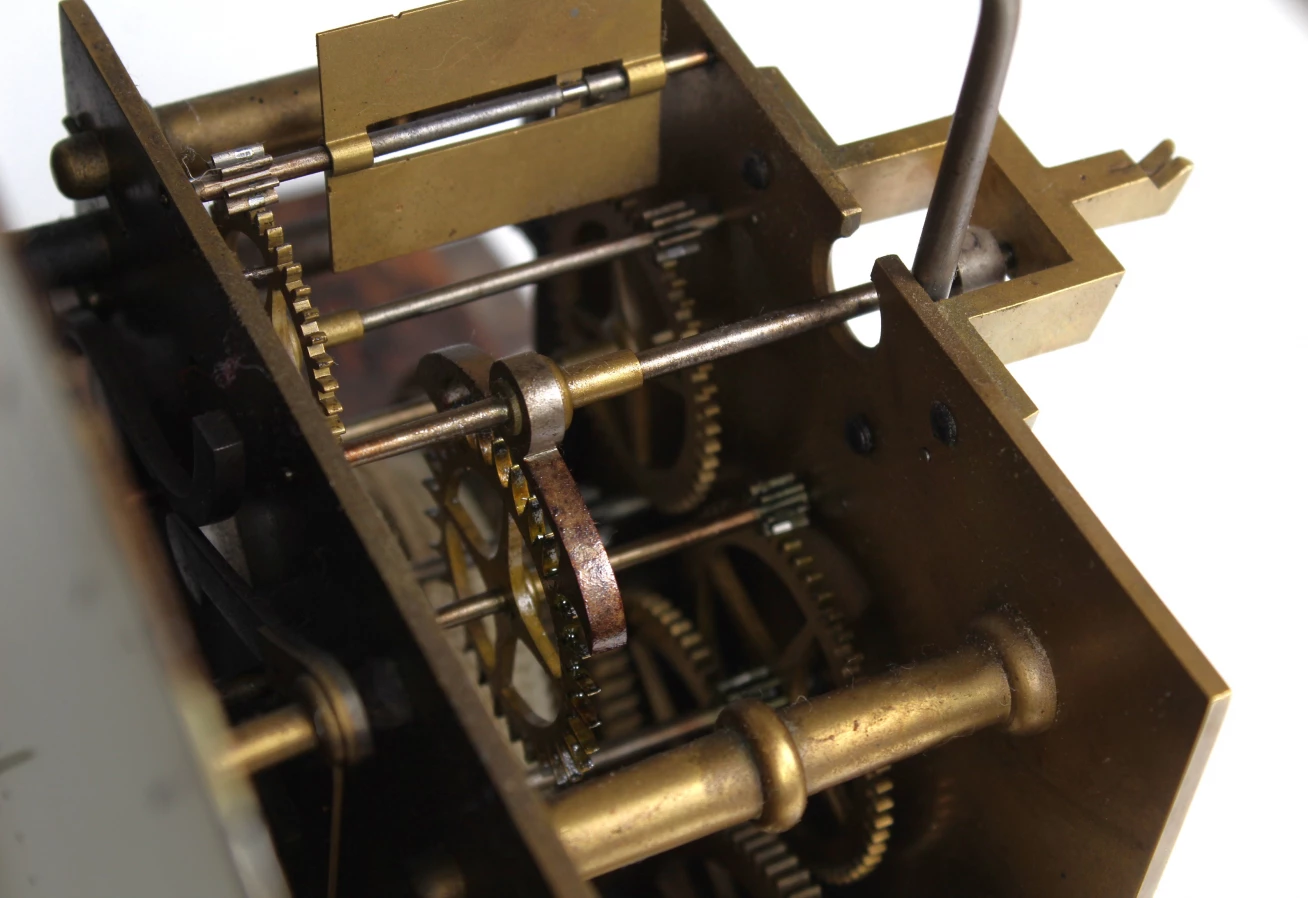

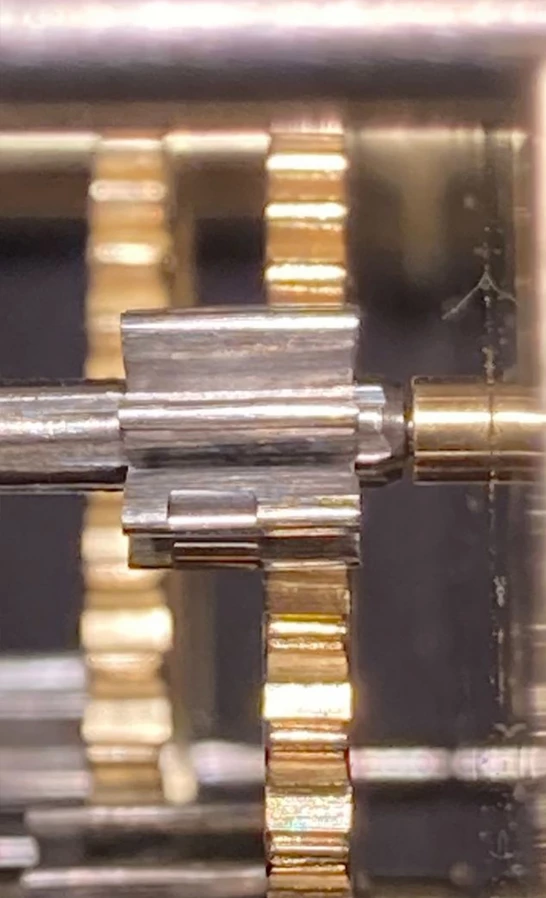

-The driving teeth of the escape wheel were particularly worn in, as were the lifting surfaces of the lever of the escapement. Grinding and polishing the lifting surfaces of this escapement would adversely change the geometry of the engagement. Therefore, in order to correct the meshing, the complete shaft of the escape wheel was axially offset. As a result, the escape wheel's driving teeth run on a new, unused track. At the same time, the teeth of the escape wheel meet a non-worn lifting surface of the armature. These measures significantly improve the power transmission at two crucial points (see photos).

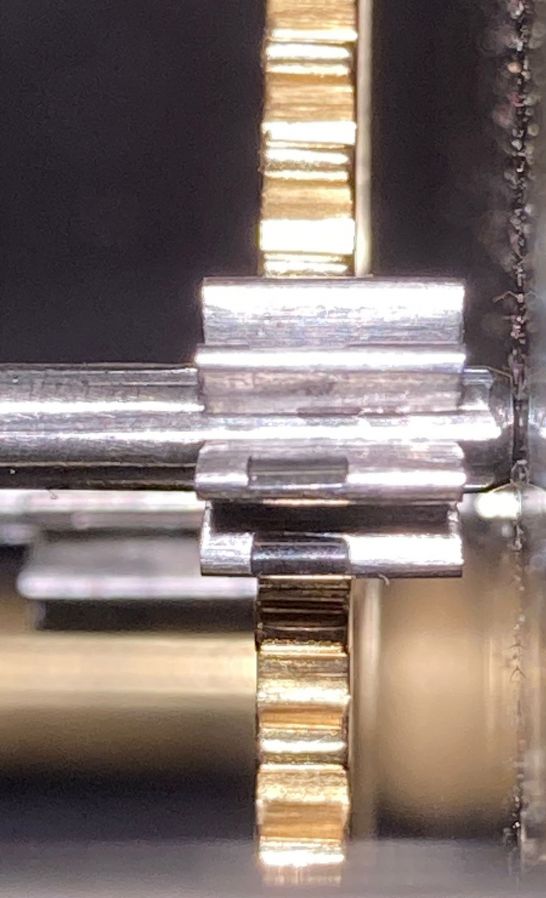

-The extremely worn-out minute wheel bearing on the drive side is also worth mentioning. It had expanded longitudinally oval to such an extent that it could not be reamed with the reamer, as is usually the case, because then the bearing bore would no longer have been properly centred. The bearing had to be filed against the direction of wear, so that the bore was once again centred in the oil counterbore and the shaft was perpendicular (see photos).

-Last but not least, new gut cords were inserted and a properly fitting winding crank was made.

Does your antique grandfather clock also need some attention?

Send us a few photos by email, WhatsApp or SMS for an initial estimate of the work involved. In addition to restoring antique grandfather clocks, we are also happy to take care of your wall clocks, table clocks or mantel clocks.

Also interesting

Restoration and brightening of an oak cupboard

Can you actually make dark furniture light again?

Restoration of a Biedermeier top chest of drawers

See here what a reappraisal can do!

Restoration of a cabinet from the Wilhelminian period

Shellac, oil or wax? What is the right surface sealant?